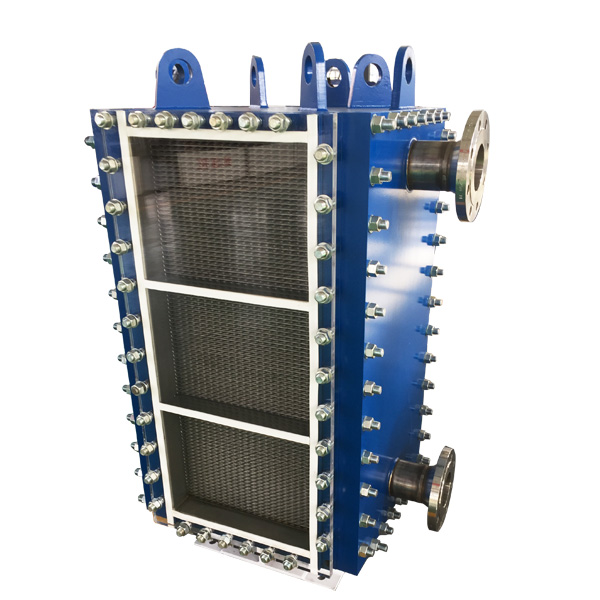

Welded Plate Heat Exchanger

Welded Plate Heat Exchanger

In case you do not find the type or model in the website

We can customized according to your request.

Contact Now

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

- WhatsApp:0086 13916147965

- Mob:0086 13916147965

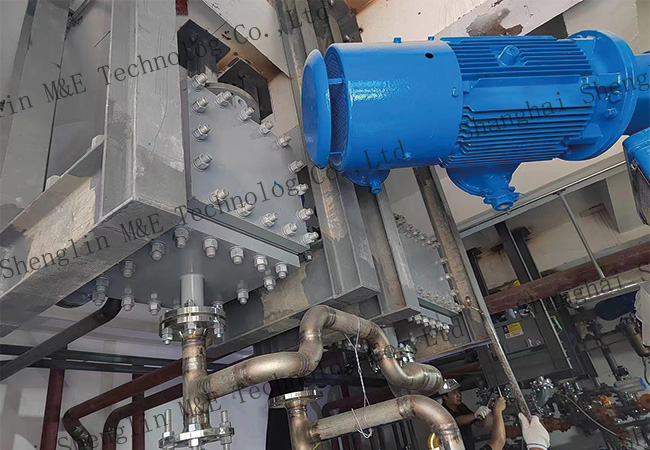

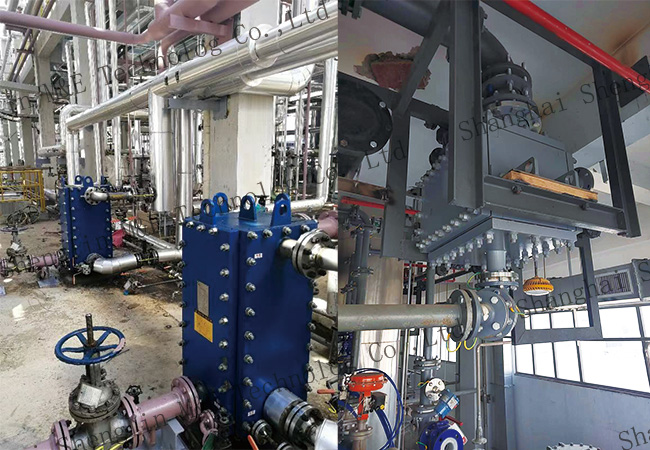

The laser frame plate heat exchanger combines the advantages of plate heat exchangers and shell and tube heat exchangers, maintaining the advantages of traditional plate heat exchangers such as high heat transfer efficiency, compact structure, high temperature resistance, good sealing performance, safety and reliability, and can also be used under higher pressure and temperature conditions. Suitable for steam condensation and liquid liquid heat exchange, especially suitable for the heat exchange needs of special media in industries such as power, petrochemical, coking, pharmaceutical, metallurgical, refrigeration, pulp and paper industry, etc.

The reasonable setting of the process ensures the reasonable matching of the heat transfer efficiency and Friction loss of the equipment. The shell adopts a Hexahedron detachable structure, which can also meet the process requirements of mechanical cleaning and chemical cleaning inside the equipment.

The reasonable setting of the process ensures the reasonable matching of the heat transfer efficiency and Friction loss of the equipment. The shell adopts a Hexahedron detachable structure, which can also meet the process requirements of mechanical cleaning and chemical cleaning inside the equipment.

What is a Welded Plate Heat Exchanger and How Does It Work?

What is a Welded Plate Heat Exchanger?

Welded plate heat exchanger is a plate heat exchanger made of a series of corrugated metal plates welded by laser or argon arc welding. The plate group and the plate group are connected by welding with molding strips. Because there is no gasket seal, it has higher temperature and pressure resistance. It can be applied to extreme working conditions of high temperature and high pressure.

Welded plate heat exchangers are divided into non-detachable fully welded plate heat exchangers, 2-sided detachable fully welded plate heat exchangers, 4-sided detachable fully welded plate heat exchangers (HFM bloc), and wide channel fully welded plate heat exchanger.

How Does a Welded Plate Heat Exchanger Work?

A welded plate heat exchanger (WPHE) is a type of heat exchanger that uses welded plates to transfer heat between two fluids. Unlike gasketed plate heat exchangers, welded plate heat exchanger do not use gaskets or seals between the plates, which makes them suitable for applications where the leakage is a concern.

The welded plate heat exchanger consists of a series of thin metal plates, which are welded together to form a series of channels or passages. The plates are designed to create a large surface area for heat transfer and are typically made of materials that have high thermal conductivity, such as stainless steel or titanium.

The two fluids that need to be heated or cooled flow through the different passages of the heat exchanger, with each fluid flowing through alternate passages. As the fluids flow past each other, heat is transferred between them through the thin metal plates.

The welded plate heat exchanger design allows for a higher degree of thermal efficiency compared to traditional shell-and-tube heat exchangers, as there is less thermal resistance between the fluids and the plates. The lack of gaskets or seals also means that welded plate heat exchanger are less prone to leakage and require less maintenance.

Welded plate heat exchanger are commonly used in applications where high pressures or temperatures are involved, such as in chemical processing, oil and gas production, and power generation. They are also well-suited for applications where the fluids being transferred are corrosive or have a high fouling potential, as the smooth surface of the welded plates makes them less prone to fouling compared to other heat exchanger designs.

Our Models

| Partial Model Parameter Table of Shenglin Laser Frame Heat Exchanger | ||||||

| Model | Outline dimension(mm) |

Maximum assembly area (m2) |

Connection diameter | Standard pressure range | ||

| Max length | width | height | ||||

| HU-06Y | 820 | 600 | 1175 | 10 | DN150 | ≤3.2MPa |

| HU-18Y | 1050 | 720 | 1285 | 35 | DN200 | |

| HU-30Y | 750 | 735 | 1350 | 21 | DN250 | |

| HU-30Y | 1250 | 720 | 1350 | 62 | DN250 | |

| HU-50Y | 950 | 910 | 2000 | 78 | DN350 | |

| HU-60Y | 1680 | 860 | 1450 | 125 | DN350 | |

| HU-75Y | 1260 | 1220 | 2860 | 295 | DN500 | ≤3.0MPa |

| HU-90Y | 1780 | 1160 | 2250 | 300 | DN500 | |

| HU-110Y | 2080 | 1160 | 2000 | 300 | DN500 | |

| HU-130Y | 2380 | 1160 | 1700 | 300 | DN500 | |

| Standard temperature range:-20℃ to 300℃ | ||||||

1. Oil refining and mining industry.

2. Petrochemical

2. Petrochemical

3. Oil & Gas

4. Energy Power

5. Metallurgy

6. Biomedical

|

|

anterior:ninguno

Related Product

+Newsmore

- 06 Sep,2023Pad Adiabatic Dry Cooler Trial Operation Before Shipment

- 06 Sep,2023828kW Adiabatic Cooling System Dry Cooler Loading

- 17 Aug,2022Flat Type Dry Cooler Finished For Canada Client

- 06 Sep,20231061kW dry cooler loading for USA client

- 31 Mar,2021Peru client Install Shenglin Adiabatic Dry Cooler At Site