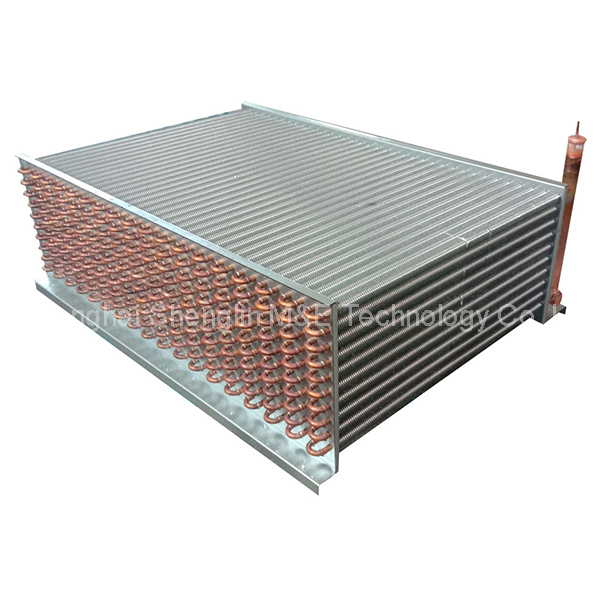

Air Cooled Coil/Fin Coil Manufacturer

Contact Now

- TEL:0086-21-35324169

- FAX:0086-21-35324166

- Email:sales@shenglintec.com

- WhatsApp:0086 13916147965

- Mob:0086 13916147965

About Shenglin:

Quality is paramount at Shenglin. Our Tube Fin Heat Exchangers adhere to the highest standards and carry international certifications such as Rohs, CE, and UL, which are widely recognized worldwide.

Material:

|

Copper Tube |

Aluminum Tube |

Bare Fin |

Copper Fin |

Hydrophilic aluminum fin |

Anti-corrosion aluminum foil |

|

|

|

|

|

|

|

|

Bare tube, inner grooved tube |

Bare tube, inner grooved tube |

For normal use like freezing and refrigeration |

For industrial equipment,subway and train air conditioning |

For indoor and transport air conditioning evaporators |

For medical, chemical and marine climate. |

Fin Pattern:

|

Tube Diamater |

Hole Space(mm) |

Row Space(mm) |

Fin Space(mm) |

Tube Material |

Fin Material |

|

ɸ5 |

19.05 |

11.6 |

1.1~2 |

Cu |

Cu, AL |

|

ɸ5 |

21 |

18.2 |

1.25~3 |

Cu |

Cu, AL |

|

ɸ6 |

13.5 |

10 |

1.3~2 |

AL |

AL |

|

ɸ7 |

25 |

21.65 |

1.4~3.0 |

AL |

Cu, AL |

|

ɸ7 |

21 |

18.2 |

1.2~3.0 |

Cu, AL |

Cu, AL |

|

ɸ7 |

21 |

12.7 |

1.3~2 |

Cu, SS, AL |

Cu, AL |

|

ɸ7 |

20.5 |

12.7 |

1.5~2 |

Cu |

Cu, AL |

|

ɸ7 |

19.05 |

12.7 |

1.3~3 |

Cu |

AL |

|

ɸ7 |

19.05 |

16.5 |

1.4~1.8 |

Cu |

Cu, AL |

|

ɸ7 |

17.6 |

13.2 |

1.3~2.5 |

Cu |

Cu, AL |

|

ɸ7.94 |

25.4 |

15.88 |

1.6~4 |

Cu, AL |

Cu, AL |

|

ɸ7.94 |

25.4 |

22 |

1.4~2.5 |

Cu |

Cu, AL |

|

ɸ7.94 |

25.4 |

19.05 |

1.2~3.3 |

Cu |

Cu, AL |

|

ɸ7.94 |

25 |

21.65 |

1.8~2.2 |

Cu |

Cu, AL |

|

ɸ7.94 |

22 |

19.05 |

1.6~2.3 |

Cu |

Cu, AL |

|

ɸ7.94 |

20.5 |

17.5 |

1.3~2 |

Cu |

Cu, AL |

|

ɸ9.52 |

31.75 |

27.5 |

2~7 |

Cu |

Cu, AL |

|

ɸ9.52 |

30 |

30 |

3~5 |

Cu |

Cu, AL |

|

ɸ9.52 |

25.4 |

22 |

1.7~5.0 |

Cu, SS |

Cu, AL |

|

ɸ9.52 |

25.4 |

19.05 |

1.2~2.5 |

Cu |

Cu, AL |

|

ɸ9.52 |

25.4 |

12.7 |

1.3~2 |

Cu, AL |

Cu, AL |

|

ɸ9.52 |

25.4 |

15.88 |

1.3~3 |

AL |

AL |

|

ɸ9.52 |

25 |

21.65 |

1.6~5.5 |

Cu, SS, AL |

Cu, AL |

|

ɸ9.52 |

25 |

25 |

2.5~4.2 |

Cu |

Cu, AL |

|

ɸ9.52 |

25 |

12.5 |

1.3~3 |

AL |

AL |

|

ɸ9.52 |

19.05 |

16.5 |

1.3~4 |

Cu, AL |

Cu, AL |

|

ɸ12 |

70 |

20 |

6~9 |

Cu |

Cu, AL |

|

ɸ12 |

50 |

25 |

1.8~7 |

Cu, SS |

Cu, AL |

|

ɸ12.7 |

75 |

25 |

8~10 |

Cu |

Cu, AL |

|

ɸ12.7 |

60 |

30 |

8~10 |

Cu |

Cu, AL |

|

ɸ12.7 |

50 |

50 |

2.8~6.0 |

Cu |

Cu, AL |

|

ɸ12.7 |

48 |

48 |

4.5~9 |

Cu |

Cu, AL |

|

ɸ12.7 |

40.5 |

35 |

4.5~12 |

Cu |

Cu, AL |

|

ɸ12.7 |

38.1 |

33 |

1.6~4.0 |

Cu |

Cu, AL |

|

ɸ12.7 |

35 |

30.3 |

1.8~3.1 |

Cu |

Cu, AL |

|

ɸ12.7 |

31.75 |

27.5 |

1.6~5 |

Cu, SS, AL |

Cu, AL |

|

ɸ14.5 |

52 |

45 |

4.5~7 |

Cu |

Cu, AL |

|

ɸ15.88 |

75 |

25 |

8~10 |

Cu |

Cu, AL |

|

ɸ15.88 |

60 |

30 |

8~10 |

Cu |

Cu, AL |

|

ɸ15.88 |

60 |

52 |

7~9 |

Cu |

Cu, AL |

|

ɸ15.88 |

50 |

50 |

2.5~12 |

Cu, SS, Ti, Cu-Ni |

Cu, AL |

|

ɸ15.88 |

38.1 |

33 |

1.6~5.0 |

Cu, SS, AL, Ti, Cu-Ni |

Cu, AL |

|

ɸ18 |

65 |

65 |

6~30 |

Cu, SS, AL, CS |

CS, AL |

|

ɸ25 |

75 |

65 |

6~30 |

Cu, SS, AL, CS |

CS, AL |

- 06 Feb,2024Happy Chinese New Year 2024!

- 01 Feb,2024Dry Cooler D4-8x910 In Stock Is On Sale! Discount!

- 06 Sep,2023Pad Adiabatic Dry Cooler Trial Operation Before Shipment

- 06 Sep,2023828kW Adiabatic Cooling System Dry Cooler Loading

- 17 Aug,2022Flat Type Dry Cooler Finished For Canada Client

- 06 Sep,20231061kW dry cooler loading for USA client

- 31 Mar,2021Peru client Install Shenglin Adiabatic Dry Cooler At Site